Busca de Produtos

PRODUTOS

Computer Controlled Biodiesel Process

Cód. EBDC

PRINCIPAIS CARACTERÍSTICAS

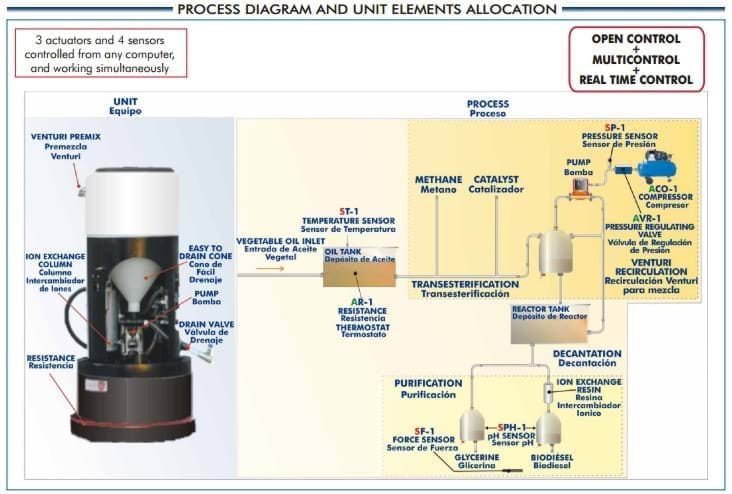

The Computer Controlled Biodiesel Process Unit (EBDC), developed by EDIBON, is a unit which allows the study of the biodiesel production cycle different stages. Different parameters that affect the whole process, as well as the obtained biodiesel quality, may also be studied.

Mais Detalhes do Produto

The EBDC unit generates 50 litres of high quality biodiesel in 24 hours. The "ingredients" required for its generation are 50 litres of raw or used oil, 8 litres of methanol and a catalyst (liquid methylate is recommended). During the process, these substances are heated, mixed, separated and purified.

The chemical reaction to make biodiesel is quite simple. Vegetable oil is a "triglyceride", in other words, there are three hydrocarbon chains at the same glycerin molecule. A certain amount of catalyst is needed to break those hydrocarbon chains. A chemical test, called titration, is needed to determine the amount of catalyst required to compensate the acidity excess in waste vegetable oils as a result of cooking. The accessories needed to carry out the test are supplied with the unit: pipettes, droppers, titrant, etc.

The catalyst is dissolved in methyl alcohol (methanol). This "premixture" is stirred strongly with the oil to enable a complete oil conversion. The mixture makes the catalyst break each hydrocarbon chain one by one, bonding it to a floating molecule of methanol afterwards to form biodiesel.

Molecules without glycerin drop to the bottom of the reaction tank, where they are eliminated.

The unit uses an external heater with safety thermostat. It is controlled through the software (PID control). It includes a pump which works with air (supplied by a compressor). This pump transfers the oil towards the reaction tank, homogenizes it, mixes the oil with the premix and mixes the oil batch in swirls. It also operates the Amberlite resin column and supplies the biodiesel to the vehicle or storage tank.

Glycerin obtained in the process is extracted through the drain valve located at the front of the unit. After removing the glycerin, a resin ion exchange integrated column facilitates the biodiesel purification process. Through a slow recirculation, this column removes soaps, glycerin and methanol excess, generating an excellent clean fuel. As long as the raw material is appropriate, the product will fulfil all the required standards for biodiesel.

Besides, the unit has two pumps, one for methanol and the other for the catalyst. They are manual pumps specially devised to be used with solvents, including alcohol.

The sensors and instrumentation provided with the unit allow:

- Know the vegetable oil preheating temperature and control it through a PID control.

- Control the air inlet pressure of the compressor which activates the circulation pump by means of a regulating electronic valve and a

pressure sensor. Agitation and recirculation levels will depend on this inlet pressure.

- Know the obtained amount (weight and volume) of biodiesel, and by-products such as glycerin, by means of a load cell.

- Know the biodiesel pH in order to ascertain its quality.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control and Data Acquisition Software Packages, for controlling the process and all parameters involved in the process.

COMPLETE TECHNICAL SPECIFICATIONS EBDC. Unit:

Anodized aluminium structure and panels in painted steel that

guarantees a good stability and resistance.

Main metallic elements in stainless steel.

Diagram in the front panel with similar distribution to the

elements in the real unit.

Wheels that facilitate the unit's mobility.

Reactor tank with inner tap (75 litres).

Oil heating tank (65 litres).

Heating band computer controlled, of 1.5 kW for the tank.

Premix bottle with couplings and hoses.

Membrane pump (maximum flow of 12 l./min.). The

pump is operated by a compressor.

Compressor, computer controlled,range: 0-6 bar

Stainless steel recirculation hose. Venturi

recirculation system for the premixing process.

Paper filter of 10 microns (located before

the biodiesel outlet tap).

Glycerin outlet tube and tap (glycerin drainage

system).

Biodiesel hose and tap.

Purification compartment with two Kg of

Amberlite (ion exchange resin column).

Plastic funnel with mesh for particles.

Regulator and air connectors.

Hoses and air connectors.

Polyethylene graduated biodiesel jerry can of 60 litres with dispenser tap.

Polyethylene graduated glycerin can of 10 litres with dispenser tap.

Plastic pump for methanol.

Plastic pump for catalyst.

Pressure regulating valve, range: 0-6 bar.

Temperature sensor “J type”.

Pressure sensor, range: 0-6 bar.

Force sensor to measure the obtained glycerin and biodiesel weight, range: 0-75 kg.

pH sensor to determine the quality of the obtained biodiesel, range: 0-14 pH.

Titration kit:

Bottle of pH indicator.

Suitable bottle for methanol.

Bottle with titrant.

2 droppers of 5 ml.

3 glass flasks.

Pipette of 5 ml.

Pipette of 10 ml with manual pump.

Plastic graduated vessel.

Large plastic graduated vessel.

Biodiesel production:

Batch of 50 l. of biodiesel every 24 hours.

Raw material needed for 50 l. of biodiesel:

50 l. of raw of used oil.

8 l. of methanol, and catalyst.

The complete unit includes as well:

Advanced Real Time SCADA and PID Control.

Open Control + Multicontrol + Real Time Control.

Own Control Software based on Labview.

National Instruments Data Acquisition board (250 KS/s (kilo samples per second)).

Calibration exercises included.

Students multipost (an entire class) by using a projector.

Ready for doing applied research, real industrial simulation, training courses possibilities, etc.

Unit is totally safe (Mechanical, Electronic/Electrical and Software safety devices included).

Results calculation and analysis software (CAL).

Several future expansions, as ESN. EDIBON Scada-Net System (many students working

simultaneously), and more.

Designed and manufactured under several quality standards.